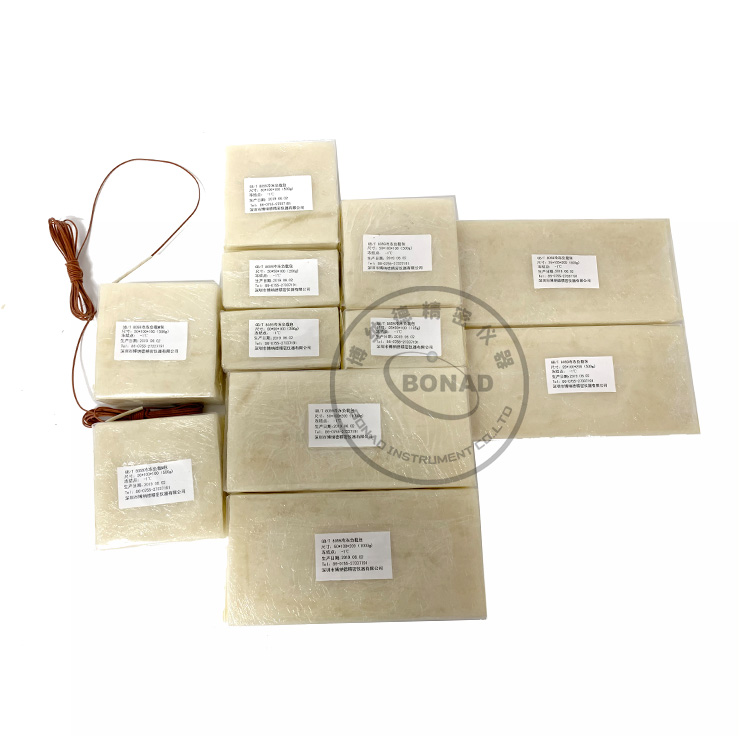

Product Description:

Name:IS 7872 Indian standard Test Packge for Deep Chest Freezer

Type:BND-RT01

Dimensions and Mass Specifications

| Sl No | Dimensions (mm) | Mass (g) |

|---|---|---|

| i) | 50 x 100 x 100 | 500 |

| ii) | 50 x 100 x 200 | 1000 |

| Sl No | Dimensions (mm) | Mass (g) |

|---|---|---|

| i) | 25 x 100 x 200 | 500 |

| ii) | 37.5 x 100 x 200 | 750 |

Tolerances for New Test Packages

*Linear Dimensions:

±2 mm for dimensions from 25 mm to 50 mm

±4 mm for dimensions from 100 mm to 200 mm

*Mass: ±2%

Composition of Each Test Package

Each test package consists of filling material and a wrapper. The filling material per 1,000 g includes:

*230 g of oxyethyl methyl cellulose

*764.2 g of water

*5.0 g of sodium chloride

*0.8 g of para-chloromethane-cresol

The freezing point of this material is -1°C, with an enthalpy value of 285 kJ/kg corresponding to a temperature of (-1 ±0.5)°C. To compensate for evaporation during preparation, approximately 4% additional water should be added.

Instructions

1. Need at below zero temperature condition when long storing, the optimum temporary is -18℃.

2. Thawing: Should be natural thawed at room temperature, don’t use such as microwave ovens, electromagnetic ovens to thaw.

3. Freezing: Beware of deformation when test package begin to freeze. Need repair timely if they have been deformed. The correct way is freezing in batches, when lower test package has completely freezing, add another one above it. This can prevents the lowermost test package by extrusion.

4. Seal: Keeping in sealed condition, once package is damaged should be repaired or discarded immediately, otherwise evaporation of water will affect the quality of test package.

1. Need at below zero temperature condition when long storing, the optimum

temporary is -18℃.

2. Thawing: Should be natural thawed at room temperature, don’t use such as microwave ovens, electromagnetic ovens to thaw.

3. Freezing: Beware of deformation when test package begin to freeze. Need repair timely if they have been deformed. The correct way is freezing in batches, when lower test package has completely freezing, add another one above it. This can prevents the lowermost test package by extrusion.

4. Seal: Keeping in sealed condition, once package is damaged should be repaired or discarded immediately, otherwise evaporation of water will affect the quality of test package.